What Size Wire for an Electric Dryer?

When it comes to setting up an electric dryer in your home, choosing the correct wire size is not only crucial for the appliance’s performance but also for ensuring the safety of your household. Installing the wrong wire size can lead to potential hazards, reduced drying efficiency, and even damage to the dryer. In this comprehensive guide, we will delve into what size wire for an electric dryer the technical aspects of electric dryers, electrical codes, wire types, and safety precautions to help you make an informed decision for your dryer installation.

What Size Wire for an Electric Dryer Recommended?

The most common wire size for an electric dryer is 10 AWG (American Wire Gauge) copper wire for a 30-amp circuit. For a 40-amp circuit, 8 AWG copper wire is typically used. However electric dryer amps, it’s essential to consult the dryer manufacturer’s specifications and local codes for precise wire size recommendations.

For long wire runs or installations that require significant power, you may need to use larger wire sizes to reduce voltage drop. In such cases, a 6 AWG or even 4 AWG copper wire might be necessary.

What is the American Wire Gauge?

American Wire Gauge (AWG) is a standard measurement system used to specify the size of electrical wires. It is commonly used in the United States to describe the diameter or cross-sectional area of conductors. The AWG system assigns a specific number to each wire size, with smaller numbers representing larger wire diameters.

For example, a lower AWG number corresponds to a larger wire size, while a higher AWG number indicates a smaller wire size. The AWG scale ranges from 0000 (4/0) to 40, with 0000 being the largest wire size and 40 being the smallest.

What gauge wire for electric dryer?

The gauge of wire needed for an electric dryer typically depends on the dryer’s power rating and the circuit amperage it requires. Most residential electric dryers require a 240-volt circuit with either a 30-amp or 40-amp circuit breaker. The following are the recommended wire gauges based on the circuit amperage:

- For a 30-amp circuit, use 10 AWG (American Wire Gauge) copper wire.

- For a 40-amp circuit, use 8 AWG copper wire.

Using the correct wire gauge ensures that the wire can handle the electrical load without overheating and provides safe and efficient operation for your electric dryer. Always refer to the dryer manufacturer’s specifications and local electrical codes for precise wire size requirements. If you have any doubts or require assistance, consult a licensed electrician for professional guidance.

Understanding Electric Dryer Power Requirements

What are the voltage and amperage specifications for electric dryers?

Electric dryers commonly require a 240-volt power supply, which is distinct from the standard 120-volt outlet used for many household appliances. Additionally, electric dryers typically run on a 30-amp or 40-amp circuit, depending on the model and power rating. This higher voltage and amperage provide the necessary power to heat the dryer element efficiently, resulting in faster drying times.

What are the common electrical ratings of electric dryers?

Most residential electric dryers have a power rating between 5,000 and 6,000 watts. Understanding these ratings helps you gauge the energy consumption of the dryer and select the appropriate wire size and circuit breaker capacity, as this may cause dryer breaker keeps tripping if not chose right.

How does wire size impact the efficiency and performance of the dryer?

The wire size plays a vital role in maintaining the performance and efficiency of your electric dryer. If the wire size is too small for the current demands of the dryer, it can lead to voltage drop issues, causing the dryer to operate inefficiently and take longer to dry clothes. Additionally, an inadequate wire size may overheat, posing a fire hazard. Conversely, using an excessively large wire size can be unnecessary and costly.

Electrical Codes and Standards

What are the National Electric Code (NEC) regulations related to dryer installations?

The National Electric Code (NEC) provides comprehensive guidelines for safe electrical installations, including those pertaining to electric dryers. These regulations cover wire sizing, circuit breaker capacity, grounding, and other essential safety aspects. Complying with NEC standards ensures that your dryer’s electrical system is safe, reliable, and up to code.

How do local building codes affect wire sizing for dryers?

In addition to the NEC, local building codes may impose specific requirements for dryer installations. These codes can vary depending on your location and may include rules related to wire size, conduit usage, and installation methods. Staying informed about these local codes is crucial to avoid compliance issues and ensure your installation meets all safety standards.

What are the consequences of non-compliance with electrical codes?

Failure to comply with electrical codes can have serious consequences. It may result in electrical hazards, invalidated insurance coverage, and even legal liabilities in the event of an accident. It’s essential to adhere to all relevant codes and standards to ensure the safety of your home and its occupants.

Calculating the Appropriate Wire Size

What factors should be considered when selecting the wire size? (distance, load, voltage drop)

Selecting the correct wire size requires considering several factors. The distance between the electrical panel and the dryer location is significant because longer distances introduce more resistance and voltage drop. The dryer’s power rating, measured in watts, determines the amount of current the dryer draws, and this, in turn, affects the wire’s ampacity requirement. Finally, voltage drop considerations help ensure the dryer receives the necessary voltage for efficient operation.

How do you calculate the wire gauge for your electric dryer?

Calculating the appropriate wire gauge involves using ampacity tables specified in the NEC or utilizing online wire size calculators. These tools take into account the dryer’s power rating, the distance from the electrical panel to the dryer, and the desired voltage drop to suggest the ideal wire size for your installation.

What are the recommended wire sizes for various dryer models and power ratings?

Different dryer models and power ratings require specific wire sizes to operate safely and efficiently. To simplify your decision-making process, we provide a comprehensive table with recommended wire sizes based on various dryer specifications, ensuring you select the perfect match for your electric dryer.

| Power Rating (Watts) | Circuit Ampacity (Amps) | Recommended Wire Size (AWG) |

| Up to 3,000 | 15 | 14 |

| 3,000 – 4,000 | 20 | 12 |

| 4,000 – 5,000 | 25 | 10 |

| 5,000 – 6,000 | 30 | 10 |

| 6,000 – 7,000 | 30 | 8 |

| 7,000 – 8,000 | 40 | 8 |

| 8,000 – 10,000 | 50 | 6 |

| 10,000 – 12,000 | 60 | 6 |

Common Wire Types for Electric Dryers

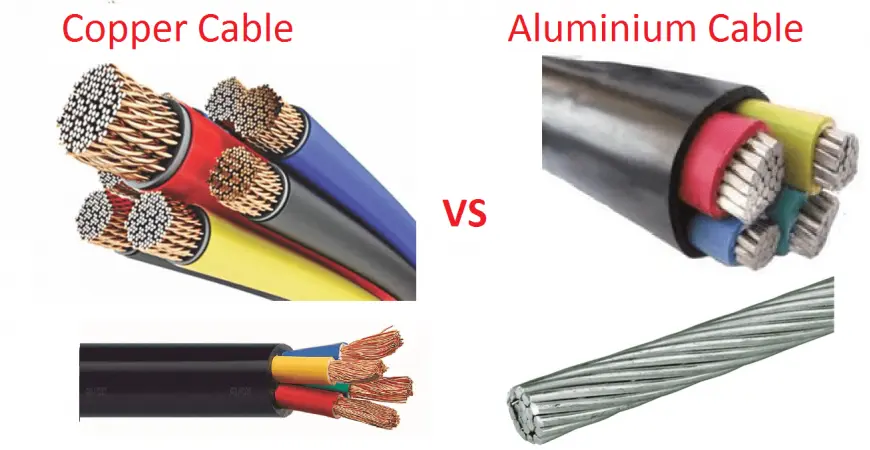

What are the different wire types available for dryer installations? (Copper vs. Aluminum)

Copper and aluminum are the two primary wire types used for electric dryer installations. Copper wires offer superior conductivity, making them more energy-efficient and less prone to heat-related issues. They are also more flexible, making installation easier. On the other hand, aluminum wires are lighter and less expensive, but they require special precautions due to their tendency to oxidize. Read 125 amp wire size guide.

What are the pros and cons of each wire type for electric dryers?

Copper wires are preferred for their higher electrical conductivity, resistance to corrosion, and overall safety. They are also widely supported by electrical codes and compatible with most dryer models. However, copper wires can be more expensive than aluminum. Aluminum wires are lighter, making them easier to work with, and cost-effective, but they require careful installation techniques to prevent overheating and potential hazards.

What safety considerations should be taken into account when using aluminum wires?

If you choose to use aluminum wires for your electric dryer installation, it is essential to follow specific safety measures. Antioxidant compounds should be applied to aluminum connections to prevent oxidation and ensure reliable conductivity. Using approved connectors designed for aluminum wiring and carefully following manufacturer guidelines will help mitigate the risks associated with aluminum wires.

Upgrading Electrical Systems for Dryer Installations

How do you assess the existing electrical system’s capacity for the dryer?

Before installing an electric dryer, it’s crucial to assess your home’s electrical system’s capacity. This involves checking the main electrical panel’s available amperage and evaluating the load on existing circuits to determine if any upgrades are necessary. A qualified electrician can assist you in this evaluation.

When and how should you upgrade the circuit breaker and panel for the dryer?

If your current electrical panel lacks the required amperage to support the dryer’s power requirements, you may need to upgrade to a higher amperage circuit breaker and panel. Upgrading the panel is a complex task that should be performed by a licensed electrician to ensure the safety and compliance of your electrical system.

Is it advisable to seek professional help for complex electrical upgrades?

Yes, We strongly advise seeking assistance from a qualified electrician with experience in handling such upgrades. Electrical upgrades such as installing a new circuit breaker and panel, can be complex and hazardous if not done correctly. A licensed electrician will ensure that the installation is up to code, safe, and compliant with electrical regulations.

Safety Precautions during Installation

What steps should be taken to ensure safety during the installation process?

Safety is of utmost importance when dealing with electricity. Before starting any work, it is vital to turn off the power at the circuit breaker specifically designated for the dryer what size breaker for electric dryer. Always use appropriate personal protective equipment (PPE) to protect yourself from electrical hazards.

How do you turn off power and perform electrical testing before starting the work?

We provide detailed instructions on how to turn off the power at the circuit breaker, ensuring there is no electrical flow to the wires you will be working with. Additionally, you should use a voltage tester to verify that the power is indeed off and that there is no voltage present.

What are the proper grounding techniques for electric dryers?

Proper grounding is essential for the safe operation of electric dryers. The grounding conductor connects the dryer’s metal frame to the ground, providing a path for electricity in the event of a fault. We explain the correct grounding methods for electric dryers, ensuring your dryer is protected against electrical malfunctions.

Troubleshooting Electrical Dryer Issues

What are some common wiring problems in electric dryers?

Identifying common wiring problems in electric dryers can help you detect potential issues early and prevent possible malfunctions. Common issues include loose connections, damaged wires, and improper grounding.

How can you address circuit overload and voltage drop issues?

Circuit overload and voltage drop can negatively impact your dryer’s performance and safety. We offer troubleshooting tips for these issues, such as redistributing loads and addressing high-resistance connections.

When is it necessary to call a professional electrician for dryer-related problems?

While some electrical dryer issues can be resolved by homeowners, certain problems require professional expertise. We highlight signs that indicate the need to seek help from a licensed electrician, ensuring that electrical repairs are done safely and correctly.

FAQ What size wire for an electric dryer

What gauge wire do I need for a 220 dryer?

For a 220-volt dryer, you will typically need a wire gauge of 10 AWG for a 30-amp circuit or 8 AWG for a 40-amp circuit. Read 220 dryer plug wiring guide, These wire sizes ensure safe and efficient operation of the dryer and comply with electrical codes.

What gauge wire for a 240-volt dryer?

A 240-volt dryer also requires a wire gauge of 10 AWG for a 30-amp circuit or 8 AWG for a 40-amp circuit. The wire size depends on the dryer’s power rating and the amperage specified by the manufacturer.

What is the best wire for a 220V dryer?

The best wire for a 220V dryer is usually 10 AWG or 8 AWG copper wire, depending on the specific dryer model and its power requirements. Copper wires are preferred for their higher conductivity and better heat resistance, ensuring safe and efficient power delivery to the dryer.

Should I use 3 wire or 4 wire for a dryer?

It is recommended to use a 4-wire setup for a dryer. A 4-wire configuration includes two “hot” wires, a neutral wire, and a grounding wire. This setup provides a safer and more reliable electrical connection compared to the older 3-wire setup, which lacks a separate grounding conductor.

Is a 3-wire dryer cord safe?

While older homes may have 3-wire dryer cords, they are not as safe as the newer 4-wire cords. The 3-wire setup lacks a dedicated grounding wire, increasing the risk of electrical hazards. It is safer to upgrade to a 4-wire dryer cord to ensure proper grounding and compliance with modern electrical standards.

Do dryers require 4 wires?

In most modern installations, dryers do require 4 wires. A 4-wire setup includes two “hot” wires, a neutral wire, and a grounding wire. This configuration ensures proper grounding and minimizes the risk of electrical shocks or damage to the dryer. Always check the manufacturer’s specifications and local electrical codes to determine the appropriate setup for your specific dryer model and installation.

Conclusion

Choosing the what size wire for an electric dryer is a critical step in ensuring optimal performance and safety. By understanding the power requirements, adhering to electrical codes, selecting appropriate wire types, and following safety precautions, you can confidently set up your electric dryer with peace of mind. Remember that complex electrical upgrades and installations should always be entrusted to a qualified electrician to guarantee compliance with regulations and safeguard your home.